Jed Soar

European Director - Technical Services & Product Performance

At TVS Eurogrip Tyres, we fully recognize the immense challenges faced by modern agriculture. The evolving demands of farming require innovative solutions, which is why we collaborate with some of the world’s leading tyre designers to develop tyres that perform efficiently both on the land and on the road. In today’s agricultural landscape, machinery manufacturers are focused not only on reducing harmful emissions but also on improving overall fuel efficiency. However, it is counterproductive for a manufacturer to enhance a tractor’s engine efficiency by 5%, only for that gain to be negated by poor tyre selection or inadequate pressure management, leading to an overall efficiency reduction of up to 15-20%.

TIGERTRAC AG TYRE RIM, SIZE AND DIAMETER CONVERSION TABLE

RIM | SRI | RCI | Approx Tyre OD (mm) | Approx Tyre OD (in) | Tigertrac 85 (Metric) | Tigertrac 85 (inches) | Tigertrac 70 | Tigertrac 65 | Tigertrac XL Wide Traction | Tigertrac Narrow | Tigertrac Harvester |

|---|---|---|---|---|---|---|---|---|---|---|---|

38″ | 800 | 44 | 1676 | 66″ | 420/85R38 | 16.9R38 | 480/70R48 | 540/65R38 | 750/65R26 26″ RIM | ||

38″ | 825 | 45 | 1650 | 65″ | 460/85R38 | 18.4R38 | 520/70R38 | 600/65R38 | 650/75R32 32″ RIM | ||

38″ | 875 | 46 | 1850 | 72.8″ | 520/86R38 | 20.8R38 | 580/70R38 | 650/65R38 | 800/65R32 32″ RIM | 800/65R32 | |

42″ | 925 | 47 | 1957 | 77″ | 520/85R42 | 20.8R42 | 620/70R42 | 650/65R42 | 900/60R32 32″ RIM | 900/60R32 |

HOW TO CHOOSE THE RIGHT TYRE FOR THE JOB?

Selecting the correct tyre is the foundation of efficiency. Tractor performance depends not just on horsepower, but on how effectively that power translates into traction. The type of tyre, whether radial, bias, or VF (Very High Flexion), directly influences load capacity, fuel efficiency, and soil protection.

Radial tyres are ideal for long hours and mixed field-road operations. Their flexible sidewalls reduce heat build-up and ensure a consistent footprint for better traction. Bias tyres, on the other hand, are more suited for heavy-duty applications or rough terrain where sidewall strength is essential. Meanwhile, VF and IF tyres represent the latest innovations, allowing up to 40% lower inflation pressure while maintaining the same load, thereby minimizing soil compaction.

Each tractor should be fitted based on its operational profile power output, implement type, and soil condition. Our specialists at TVS Eurogrip Tyres can help match the correct pattern, size, and construction to your workload, ensuring maximum performance and fuel savings.

OPTIMIZING TYRE PRESSURE: THE KEY TO OPERATIONAL EFFICIENCY

The next critical step to improving efficiency is selecting the correct operating pressure. This factor is universally acknowledged as essential for optimal tractor performance. The process begins by determining the tractor’s unballasted weight, a step often overlooked by operators who frequently over-ballast their tractors without considering the load effects that attached equipment, such as trailers, may have. Over-ballasting can lead to unnecessary strain and inefficiencies.

At TVS Eurogrip Tyres, our agricultural specialists are available to assist you with this critical step. By correctly calculating the ballast requirements, we can also determine the ideal operating pressure for your tractor. Tyre pressure affects two major factors that directly influence overall tractor efficiency: slippage in the field and rolling resistance on the road.

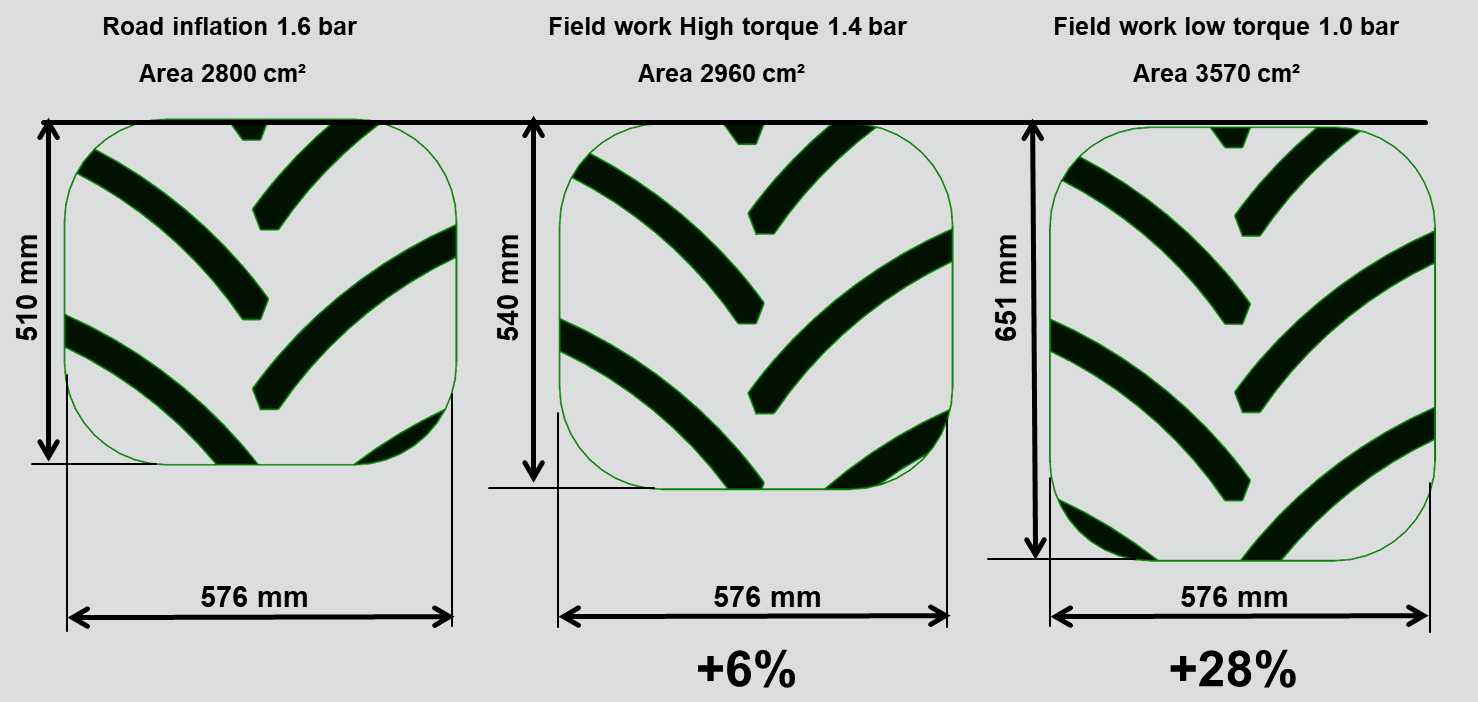

The diagrams below illustrate how tyre pressure influences the tyre’s footprint and performance:

Inflation pressure and load:

SIZE : 650/65R42 | LOAD: 4300kg

Field Operations: In field work, correct tyre pressure minimizes slippage, which should be maintained between an accepted rate of 8-12% for ploughing operations. Both excessive and low slippage can negatively impact fuel consumption and performance. Excessive slip leads to a reduction in traction, while low slip places unnecessary stress on the gearbox and transmission, further diminishing the tractor’s efficiency.

Road Operations: For road use, a higher tyre pressure reduces the tyre’s contact patch with the surface, thereby decreasing rolling resistance. As the diagram demonstrates, a smaller footprint results in less friction, which is essential for fuel efficiency on hard surfaces. However, excessive tyre pressure can lead to uneven wear and reduced tyre lifespan.

MAXIMIZE TRACTION AND REDUCE SOIL COMPACTION

Traction efficiency determines how much of the engine’s torque is effectively transferred to the ground. Excessive wheel slip wastes fuel and damages soil structure, while inadequate slip reduces pulling efficiency. Ideally, wheel slip should be maintained between 8–12% in field operations, a balance that optimizes traction without causing excessive soil disturbance.

Tyres with a wider footprint or flotation design help distribute weight evenly, reducing rutting and soil compression. Maintaining correct inflation pressure further ensures the tyre lugs engage the soil uniformly. For soft soils, reducing pressure slightly allows more tread contact, improving grip. On firm ground, higher pressure prevents over-flexing and lug deformation.

Farmers who invest in proper ballast adjustment and slip monitoring often experience fuel savings of up to 15%, longer tyre life, and more consistent yields. Over time, this not only protects the land but also enhances the overall return on investment for machinery and tyres alike.

MAINTENANCE PRACTICES THAT ENHANCE TYRE EFFICIENCY

Even the most advanced tyres underperform without proper maintenance. A simple checklist can significantly extend their lifespan and operational efficiency:

1. Regular Pressure Checks – Tyre pressure fluctuates with temperature and load. Weekly checks help ensure consistent performance and prevent heat-related damage.

2. Visual Inspections – Look for cracks, cuts, or irregular wear patterns. Early detection prevents costly downtime.

3. Rotation and Alignment – Periodic rotation distributes wear evenly, while proper alignment enhances traction and reduces rolling resistance.

4. Cleaning and Storage – Remove debris after fieldwork and store tractors under cover to prevent UV damage or rubber hardening.

Proper maintenance not only extends tyre life but also supports sustainability by lowering replacement frequency. At TVS Eurogrip, we recommend farmers follow a structured tyre management plan with inspection logs and seasonal adjustments to maintain peak efficiency throughout the year.

CONCLUSION

In summary, choosing the correct tyre pressure, along with regular monitoring, is crucial for achieving optimal efficiency, whether in the field or on the road. Our team at TVS Eurogrip Tyres is dedicated to providing expert guidance to ensure that your machinery operates at its highest potential.

Frequently Asked Questions (FAQs)

How much can tyre choice affect tractor efficiency?

The right tyre and correct pressure can improve overall fuel efficiency by 10–20% while extending tyre life and reducing slippage.

Why are radial tyres more efficient than bias tyres?

Radial tyres flex more easily, maintaining a larger, more consistent footprint that improves traction and reduces rolling resistance, ideal for long hours and road transport.

What tyre pressure is best for field operations?

Field work typically requires lower pressures for better traction. Exact figures depend on load and soil type; consult your dealer or the manufacturer’s inflation guide.

Can over-ballasting reduce efficiency?

Yes. Excess ballast increases soil compaction and fuel use. Properly balancing the tractor prevents unnecessary strain on tyres and transmission.

How can I reduce soil compaction caused by tyres?

Use VF or IF tyres with lower inflation pressures, maintain correct alignment, and avoid working in overly wet conditions that deepen rutting.

How often should tyre maintenance be performed?

Visual inspections weekly and full checks monthly are ideal. Adjust pressures seasonally and before heavy workloads to maintain consistent performance.