Jed Soar

European Director - Technical Services & Product Performance

Off-highway tires (OHT) are critical components in industries like construction, mining, agriculture, and forestry, where they endure demanding environments. The integrity of these tires is paramount, as they support heavy loads, navigate challenging terrains, and ensure operational efficiency. When these tires suffer punctures or damage, the correct repair of tubeless tires becomes crucial to maintain safety, performance, and cost-efficiency.

Understanding Off-Highway Tubeless Tires

OHT tires differ from standard vehicle tires in their size, structure, and application. Most OHTs use tubeless tires, which are designed to seal directly against the wheel rim, eliminating the need for an inner tube. This design allows the tire to operate at lower pressures and reduces the risk of tube pinch flats. Tubeless tires also improve heat dissipation, essential in high-load, high-friction environments.

Given the extreme conditions these tires operate under, damage can occur from sharp objects like rocks, debris, or construction materials, leading to punctures. When such damage happens, the correct repair method becomes critical to extending the tire’s lifespan and ensuring operational safety.

Why Proper Tubeless Tire Repair Is Important?

1. Safety

OHT tires, due to their size and load-bearing capacity, present significant risks when they fail. A poorly repaired puncture can lead to catastrophic failure, jeopardizing the safety of operators and machinery. The extreme conditions these tires face, from rough terrains to heavy loads, demand that repairs restore the tire’s structural integrity to its original state. Incorrect repairs, or “temporary fixes,” can lead to blowouts, sidewall failures, or leaks, potentially causing accidents or costly downtime.

2. Maintaining Tire Longevity

OHT tires are a significant investment, and their longevity is essential for cost management in industries like mining and construction. Proper repair methods ensure that the punctured area is correctly sealed and the tire’s strength is restored. Incorrect or substandard repairs can lead to recurring issues, ultimately shortening the tire’s lifespan. A correctly repaired tire can continue to operate at full capacity, ensuring that the initial investment in the tire is maximized.

3. Preserving Tire Performance

OHT tires are designed to provide maximum traction, stability, and load-bearing capacity in tough environments. Improper repairs can affect these performance parameters. For example, a puncture that is incorrectly patched might not maintain the tire’s air pressure as effectively, leading to reduced performance in terms of traction or stability. Over time, the tire might also deform, causing uneven wear, reduced fuel efficiency, and compromised machine handling.

4. Minimizing Downtime and Operational Costs

Equipment downtime is costly in any industry, especially in high-demand environments like construction or mining, where delays can result in significant financial losses. Proper tubeless tire repairs reduce the likelihood of future failures and unplanned maintenance. By ensuring the tire is repaired correctly the first time, operators can minimize the chances of recurring problems, thus reducing downtime and the need for additional repairs or tire replacements.

5. Preventing Secondary Damage

An improperly repaired OHT tire can lead to secondary damage to the tire itself or the vehicle’s suspension system. For instance, an air leak from a poorly sealed repair could cause uneven tire pressure, which, over time, leads to uneven wear and affects the machine’s performance. Additionally, if the tire fails under load, it can damage the vehicle’s undercarriage, suspension, or even cause equipment instability.

Key Steps in Correct Tubeless Tire Repair

To ensure the best outcomes, OHT tire repairs should be carried out by trained professionals using the correct tools and procedures. Here are key steps to ensure a proper repair:

1. Inspect the Damage Thoroughly

Not all punctures or damages are repairable, especially in OHT tires. Damage to the sidewalls or severe cuts may require tire replacement rather than repair. A thorough inspection identifies whether the damage is within safe repairable limits.

2. Cleaning and Prepping the Repair Area

Proper cleaning of the damaged area is essential to ensure the patch or plug adheres effectively. Dirt, moisture, or debris can compromise the repair process, leading to air leaks or patch failure.

3. Selecting the Correct Repair Method

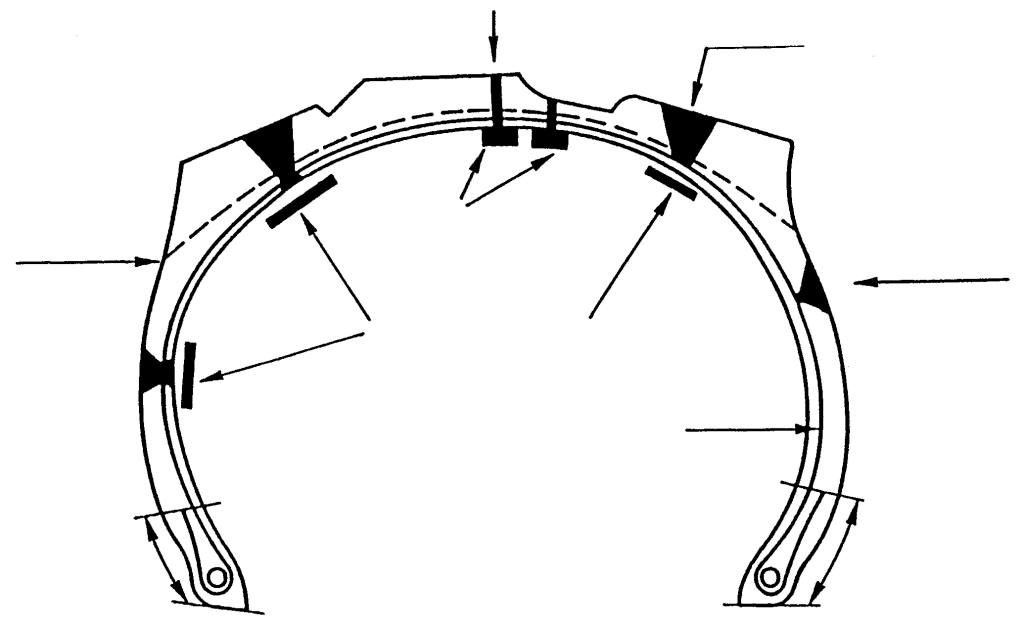

Depending on the type and size of the puncture, the repair method may vary. Small punctures from nails or sharp objects can be repaired using Combi type (mushroom) to stem and patch, this will depend on the injury size and its angle of entry in to the tire. Larger damage may require a combination of internal patches and vulcanization, a process that involves bonding rubber to the damaged area using heat and pressure.

Combi Type

Stem & Patch combo

Stem & Patch combo

4. Ensuring Proper Seal

For tubeless tires, maintaining an airtight seal is critical, an inner liner sealant should be used to cover any open buffed section of the inner liner surrounding the repaired area . After the repair, the tire should be reinstalled on the rim and checked for leaks using a pressure gauge or soap solution. Ensuring that the repair has completely sealed the puncture prevents future issues.

5. Monitoring Tire Performance After Repair

Even after a successful repair, monitoring the tire’s performance over time is essential. Operators should regularly check for signs of air loss, uneven wear, or vibrations, as these could indicate that the repair is failing.

When to Repair vs. Replace an OHT Tyre?

Not every off-highway tyre injury qualifies for repair. Knowing when to fix or replace saves both money and lives.

Repairable Damage: Small tread punctures or nail holes less than 12 mm, with no sidewall or shoulder penetration, are typically safe for stem-and-patch or vulcanized patch repair. After cleaning, inspection, and buffing, the repaired zone can restore up to 90 % of the original strength when performed correctly.

Replace Instead of Repair: Damage that exposes belts, distorts bead seating, or cuts across the sidewall compromises carcass integrity. In such cases, continuing to operate the tyre increases the risk of blowout and mechanical damage to suspension or hub assemblies.

Establishing a clear repair-versus-replace protocol helps maintenance teams avoid guesswork. Pair it with documentation photos, injury maps, and repair logs to ensure traceability across the tyre’s service life.

Environmental and Economic Benefits of Correct Repairs

Proper tubeless repairs don’t just extend service life, they significantly cut costs and waste. Every off-highway tyre saved from early disposal prevents hundreds of kilograms of rubber from entering the waste stream.

In mining or construction fleets, where tyre replacement cycles can cost thousands per unit, successful repairs reduce material usage and logistics burdens. Repairs also save energy compared with manufacturing new tyres, lowering the carbon footprint of the entire operation.

On the financial side, a high-quality repair typically costs 5–10 % of a replacement while preserving full operational performance. This translates into measurable ROI for equipment operators.

By incorporating tyre repair sustainability metrics into procurement or ESG reporting, companies can highlight efficiency gains while reinforcing environmental compliance.

Training, Tools, and Quality Assurance in Tyre Repair

The reliability of a repaired OHT tyre depends entirely on technician skill and tooling. Professional training ensures that operators recognize repairable damage, follow safety protocols, and maintain consistent standards.

Essential Tools: Buffing machines, inner-liner sealants, curing units, and calibrated pressure gauges are mandatory for achieving airtight finishes. Using unapproved materials or skipping curing time is the most common cause of repair failure.

Quality Assurance Steps:

1. Record tyre serial number and repair type.

2. Conduct pressure retention tests after mounting.

3. Reinspect after 50–100 hours of service for early leaks or delamination.

Partnering with certified service centres or OEM-endorsed repair programs builds long-term reliability. Over time, consistent QA reduces downtime, warranty claims, and the risk of catastrophic field failures.

Conclusion

In the world of off-highway tires, where safety, performance, and cost-efficiency are paramount, proper tubeless tire repair is essential. A well-repaired tire ensures that heavy-duty vehicles can continue to operate in challenging environments without unnecessary risk or downtime. Industries that rely on OHT tires must invest in proper training, tools, and repair techniques to maximize tire longevity and maintain the safety of their operations.

Ignoring or performing substandard repairs may result in costly failures, reduced tire life, and compromised safety. Therefore, understanding and implementing the correct repair procedures for tubeless OHT tires is not just a matter of good practice—it is a necessity for sustaining efficient and safe operations in demanding industries.

Frequently Asked Questions (FAQs)

Why is correct repair important for OHT tyres?

Off-highway tyres handle extreme loads and terrain. A poor repair compromises carcass strength and can cause air leaks, heat build-up, or sudden failure in operation.

What’s the difference between plug, patch, and vulcanized repairs?

A plug seals the hole externally, while a patch covers the inner liner. Vulcanized repairs fuse both chemically and thermally, providing the most durable solution for large OHT tyres.

Can sidewall cuts in tubeless tyres be repaired?

Minor surface cuts can sometimes be stabilized, but deep sidewall or bead damage should never be repaired. Such damage alters structural integrity and requires full replacement.

How long does a professional tubeless repair last?

When done correctly under controlled curing and inspection, a vulcanized repair can restore up to 90 % of the tyre’s original strength, lasting until natural tread wear ends.

What tools are essential for safe OHT tyre repair?

Certified workshops use buffing tools, bonding agents, curing presses, and calibrated air gauges. Skipping any step risks delamination or premature air leakage.

How can operators prevent frequent punctures or leaks?

Maintain correct pressure, conduct visual checks before every shift, avoid overloading, and ensure rims are free from rust or burrs that could compromise the bead seal.