Aron Calvin Vijaykhar

Global Product Manager | Marketing & Brand Management Head

When you are buying new rubber for your tractor, the price tag is often the first thing you look at. We get it. Tires are a major expense. When you see a bias-ply tractor tyre listed for significantly less than a radial one, it is tempting to save the cash and stick with the “old reliable” technology.

But in modern agriculture, the “cheaper” tire often ends up costing you more.

The debate of Radial vs Bias is not just about rubber construction; it is about farm profitability. While bias tires have served us well for decades, radial tires are better for your tractor in almost every performance category that matters: traction, fuel efficiency, and soil health.

In this guide, we will break down the differences between radial vs bias tyres, explain why the upgrade pays for itself, and help you decide if it is time to make the switch.

What is the Engineering Difference?

To understand why radials perform better, you have to look inside the tire.

Bias-Ply Tires (The Old Guard)

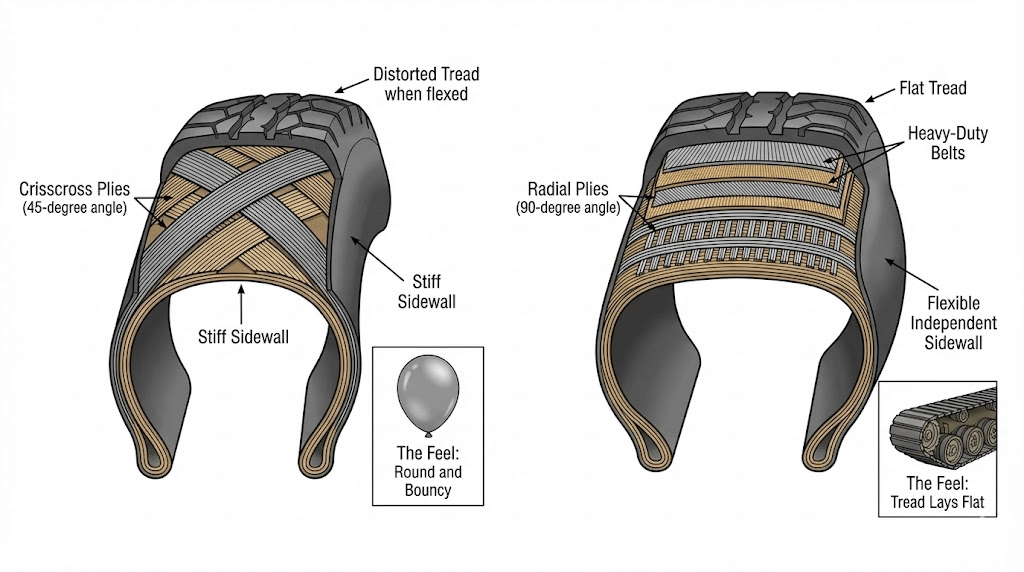

Bias (or diagonal) tires are built with layers of rubber-coated fabric (plies) that run diagonally at about a 45-degree angle from bead to bead. These layers crisscross each other.

- The Result: A very stiff, rigid structure. The sidewall and the tread work as one unit. If the sidewall flexes, the tread distorts.

- The Feel: Think of it like a balloon. It’s round and bouncy.

Radial Tires (The Modern Standard)

Radial tractor tyres are constructed differently. The ply cords run 90 degrees across the tire (radially) from bead to bead. On top of these cords, there are heavy-duty belts (often steel or fabric) under the tread.

- The Result: A “two-part” system. The sidewall can flex and bulge independently from the tread.

- The Feel: Think of it like a tank track. The tread lays flat while the sidewall absorbs the bumps.

5 Reasons Why Radial Tires Are Better for Your Tractor

If you are running a utility tractor for simple yard work, a bias tire might be fine. But for field operations, the radial vs bias comparison heavily favors the radial. Here is why.

1. Superior Traction

Because the sidewalls of a radial tire are flexible, they allow the tread to flatten out when it hits the ground. This creates a much larger agricultural tyre footprint.

- Bias: Has a round contact patch (like a basketball). Only the center lugs dig deep.

- Radial: Has a rectangular contact patch. More lugs engage the soil at the same time.

This increased contact area means better grip. Studies show radial tractor tyres can provide 10-15% better tractor tyre traction than bias tires. That means less slip, less wasted time, and more work done per hour.

2. Reduced Soil Compaction (Crop-Friendly Tyres)

Your soil is your capital. If you crush it, you lose yield. Because bias tires are stiff, they concentrate the tractor’s weight into a small, narrow area. This acts like a pressure point, driving compaction deep into the root zone.

Radial tires act as soil compaction reduction tyres. Their wide, flat footprint spreads the weight over a larger area, significantly lowering the ground pressure. If you want crop-friendly tyres that help maintain soil porosity for better water absorption and root growth, radials are the only choice.

3. Fuel Efficiency

Wheel slip is the enemy of fuel economy. When your tires spin, you burn diesel without moving forward. By providing better grip, fuel-efficient tractor tyres (radials) reduce slip. Additionally, radials have lower “rolling resistance” on hard surfaces. They don’t fight against the ground as they roll.

The Math: Switching to radials can save 3-5% on fuel bills. Over the life of the tire (which can be thousands of hours), that savings alone often covers the extra upfront cost.

4. Longer Tyre Life

Long-lasting farm tyres are essential for keeping maintenance costs down.

- Bias: Because the tread distorts and “squiggles” every time the tire rotates, it creates heat. On the road, this heat destroys rubber rapidly. The rounded profile also means the center lugs wear out much faster than the shoulders.

- Radial: The steel belts keep the tread flat and stable. It doesn’t squiggle, so it runs cooler. This leads to more even wear and a significantly longer lifespan, especially if you do a lot of road travel between fields.

5. Ride Comfort

If you spend 10 hours a day in the cab, you know that a rough ride leaves you exhausted. Tractor tyre ride comfort is vastly superior in radials. The flexible sidewall acts like a secondary shock absorber, soaking up bumps and ridges. A bias tire, being stiff, transfers every jolt directly to the operator’s seat.

When to Stick with Bias-Ply (Yes, They Still Have a Role)

We are pushing radials hard, but is there ever a case for bias-ply tractor tyres? Yes.

Bias tires are superior in:

- Forestry and Clearing: The stiff sidewalls are much more resistant to punctures from tree stumps, jagged rocks, or stiff stalks. If you are working in a forest or a scrap yard, the flexibility of a radial is actually a weakness.

- Side-Slope Stability: On extremely steep hillsides, the stiff sidewall of a bias tire provides less “wallow” or tipping sensation than a soft radial.

- Cost-Sensitive Utility: If you have an old tractor that only runs 50 hours a year for light mowing, the high cost of a radial upgrade might not be justifiable.

IF and VF Technology

Radial technology hasn’t stopped evolving. Today, we have tyre flexion (IF / VF) radial tyres.

- IF (Increased Flexion): Can carry 20% more load at the same pressure as a standard radial.

- VF (Very High Flexion): Can carry 40% more load at the same pressure.

These heavy-duty tractor tyre benefits allow farmers to carry massive planters or sprayers without having to over-inflate their tires, keeping soil compaction to an absolute minimum.

How to Maintain Your Tractor Tyre Traction?

To get these benefits, you must manage them correctly. The most critical factor is tyre inflation and pressure management.

- Bias: Needs high pressure to keep its shape.

- Radial: Needs the correct (often lower) pressure to perform. If you over-inflate a radial tire (making it hard), you lose all its benefits. It effectively becomes an expensive bias tire.

Tip: Always consult your load/inflation tables. For farm tyre maintenance, check pressures weekly. A radial tire may look flat when it is actually at the perfect pressure, and the “bulge” is where the traction comes from!

Conclusion

The verdict on Radial vs Bias is clear for most farmers. If you work in the field and care about fuel, time, and soil yield, radial tractor tyres are the better investment. They might cost more today, but they pay you back with every acre you cover.

Your tractor works hard. Give it the footwear it deserves.

Frequently Asked Questions (FAQs)

Can I put radial tires on old rims?

Usually, yes. Radial vs bias tires often fit on the same rims, provided the rim width and diameter are compatible with the new tire size. However, always check with your tire dealer, as some older rims may not handle the bead seating of modern radials.

Why do radial tires look flat?

This is the tyre flexion at work! The sidewall bulge is intentional. It allows the tread to sit flat on the ground. If you inflate it until the bulge is gone, you are over-inflating and losing tractor tyre traction.

Are radial tires better for loaders?

It depends. For general loader work, radials are fine and offer comfort. However, for extreme heavy lifting where stability is key, some operators prefer the stiffness of bias-ply tractor tyres to prevent the tractor from swaying.

How much fuel can I really save with radials?

Real-world data suggests a 3-6% savings is common. For a tractor burning 10 gallons an hour over 500 hours a year, that is significant money staying in your pocket, making them truly fuel-efficient tractor tyres.

What is the difference between R-1 and R-1W radials?

R-1 is a standard tread depth. R-1W (like the TVS Eurogrip AR 4005) has a tread that is about 20% deeper. This offers longer wear life and better grip in wet, sticky soils common in Europe and parts of the US.