Jed Soar

European Director - Technical Services & Product Performance

In the world of Off-Highway Tyres (OHT), there’s one deceptively simple concept that continues to be misunderstood—even by seasoned professionals: deflection.

Understanding and identifying correct tire deflection is critical to achieving optimal performance, extending tyre life, and, crucially, spotting problems before they become expensive failures.

Yet, in my years in the field—across continents and countless job sites—I’ve met many people who’ve spent their careers around tyres without truly grasping this fundamental principle.

Let’s strip it back to basics.

What Is Tyre Deflection, Really?

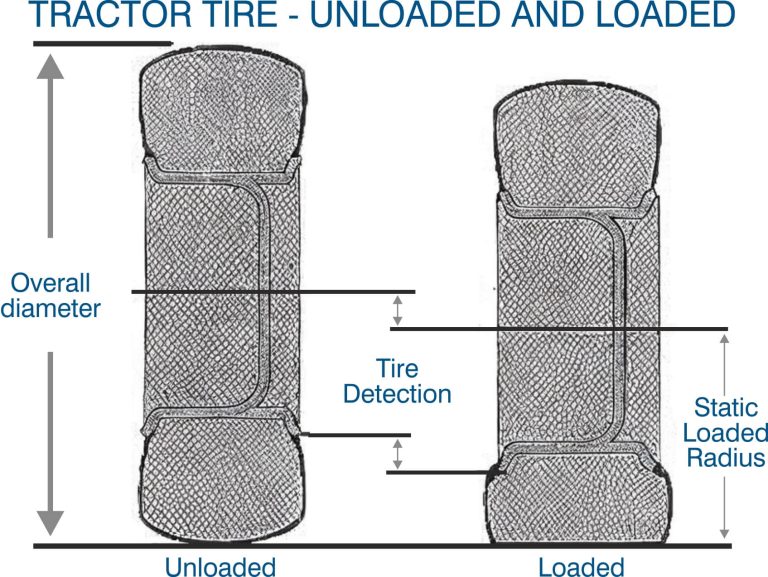

Deflection is, quite simply, the bulge you see in a tyre where it meets the ground under load. That slight curvature in the sidewall? That’s it. It may seem trivial, but this visual cue can tell you a lot about whether a tyre is doing its job—or heading toward trouble.

It’s also one of the most underutilized indicators in field operations, whether we’re talking agriculture, earthmoving, or even road transport.

A Simple Test That Delivers Big Insights

When training field fitters—especially those new to the game—I always start with a practical lesson that drives home the importance of deflection.

Here’s how it goes:

- Let’s say your inflation gauge is broken or unreadable (not uncommon on a busy site).

- Fit the agricultural tyre, seat it on the rim, and let the machine rest on it with its own weight.

- Now observe. If there’s a modest bulge—just enough curvature in the sidewall—you’re on the right track.

- If the machine is already connected to a plow or other implement, raise it off the ground. This shifts the weight to the rear tyres.

- Check the deflection again. Ideally, we’re aiming for 25–30% deflection under this loaded condition.

This “rule of thumb” method often surprises newcomers. After adjusting the pressure to achieve the correct deflection, we then compare the results with a calibrated gauge and the manufacturer’s technical data—and it nearly always aligns. That’s the power of knowing what to look for.

For VF (Very High Flexion) tires, the concept still applies, but with a greater deflection range—typically around 45%. The principle remains the same.

Why This Matters Across All Sectors

So why am I sharing this?

Because too many users and even some fitters shy away from deflection as a diagnostic or setup tool. This isn’t just an agricultural issue—it applies to earthmoving, trucking, and everything in between.

Too much deflection? You’re generating excess heat in the sidewall and shoulders. That leads to premature failure.

Too little deflection? Expect excessive wear, reduced performance, and an increased risk of external carcass damage.

Take flotation radials on ag trailers. I’ve lost count of how many times I’ve heard, “The tyre looks half flat, I can’t run it that low.” Yet, that low-pressure bulge is what gives the tyre its flotation capability—especially compared to the old-school bias-ply or even those 40×14 aircraft tyres we used to see on Larrington trailers in the ‘90s.

How Tire Deflection Changes Effective Radius and Performance

Every time a tyre flexes under pressure, its tire deflection changes effective radius, slightly altering the way it rolls on the ground. A tyre that deflects correctly maintains steady contact with the surface, ensuring balanced traction and reduced vibration. But excessive tire deflection under load can shorten the effective rolling radius, forcing the machine to work harder and increasing fuel consumption.

In contrast, too little deflection means less surface grip and a harsher ride. For giant deflect tires or large radials used in OTR and agricultural equipment, even a few millimeters’ variation can impact torque delivery and braking efficiency. Understanding this subtle but critical relationship helps operators adjust inflation pressure and load balance to get maximum stability, safety, and fuel economy from every tyre rotation.

How to Manage Over-Deflection and Sidewall Stress

One of the biggest causes of tyre fatigue in heavy-duty applications is over deflection tire when the sidewall compresses beyond its designed limit. This often happens under high loads or when pressure drops below recommended levels. As the sidewall bends excessively, internal cords stretch and heat builds up, weakening the structure over time.

Proper inflation matching the commercial tire deflection weight is key. Operators should watch for early signs like uneven tread wear, shoulder cracks, or visible sidewall deflection tire patterns. Even small discrepancies can lead to downtime on construction or agricultural sites. A consistent monitoring routine not only extends tyre life but also improves stability and operator comfort under demanding load cycles.

Back to Basics: Educate Before You Sell

This brings me to a key message I’ve repeated time and time again: Education must come before sales.

We can run as many sand-pit demos and compaction trials as we like, but if we’re not teaching users the fundamentals—like how to read tyre deflection—then we’re wasting both our time and theirs.

Thankfully, there are some forward-thinking farmers, contractors, and dealers out there who have embraced the newer technologies and best practices. But they remain the exception, not the rule.

Until the industry commits to educating users on how this technology works in the field, we risk falling back into outdated habits—and the bias and aircraft tyres of old.

Solid Tyres and the Concept of Zero Deflection

Unlike pneumatic tyres, solid tire deflection behaves differently. These tyres don’t visibly bulge under load, yet they experience internal compression where the rubber compounds deform slightly to absorb impact. In industrial settings, like forklifts, port handlers, and compactor,s this controlled rigidity improves stability but reduces ride comfort.

While the absence of air eliminates puncture risks, it also removes the flexibility that helps pneumatic tyres adapt to uneven terrain. For heavy static loads, however, solid tyres maintain consistent footprint pressure, making them ideal where downtime or deflation isn’t acceptable. Understanding this distinction helps users choose the right tyre structure for their machinery and work environment.

Final Thought

The tyre business isn’t clever. If it were, I wouldn’t be in it.

But it does require curiosity, attention to detail, and a willingness to learn (and teach) the basics. So next time you’re in the field, take a moment to check that deflection. It might just tell you more than your gauge ever could.

Frequently Asked Questions (FAQs) on Alignment in Agriculture

What is tire deflection and why is it important?

Tire deflection is the natural bulge seen where a tyre contacts the ground. It helps distribute load evenly and indicates whether inflation and load are balanced. Monitoring it ensures longer tyre life and better traction.

How does tire deflection under load affect performance?

When tire deflection under load is within range, it enhances comfort and grip. Too much or too little flex can reduce efficiency, traction, and cause premature wear.

What problems occur due to over deflection tire stress?

Excessive bending generates heat in the sidewall, leading to fatigue and cracking. Over time, it compromises safety and can cause sudden failure under heavy loads.

Do giant deflect tires offer better performance for OHTs?

Giant deflect tires and VF tyres are engineered for greater flexibility. They allow lower inflation pressures while carrying heavy loads, improving flotation and reducing soil compaction.

How does tire deflection change effective radius?

As tire deflection changes effective radius, the rolling circumference decreases slightly. This impacts torque delivery, speed calibration, and fuel efficiency, especially in high-load conditions.

Is there any tire deflection in solid tyres?

Yes, even solid tire deflection exists internally as compound compression. However, it’s minimal compared to air-filled tyres, offering stability rather than flexibility.